Non-destructive

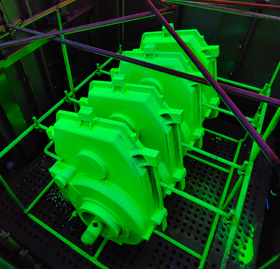

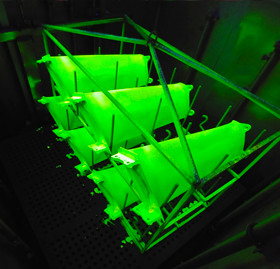

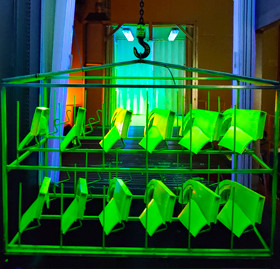

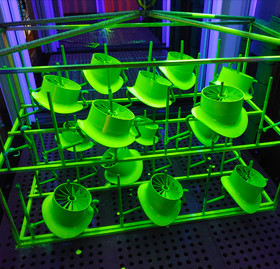

Fluorescent Penetration Inspection

Objective

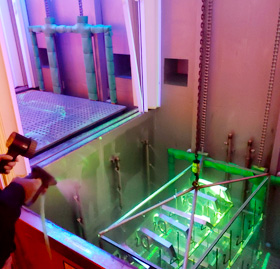

To detect potential defects or actual defects that may disrupt the product quality, fluorescent penetrant are spread over the product surface to confirm the location, shape and size of the defects.

Characteristics

1) Main Characteristics

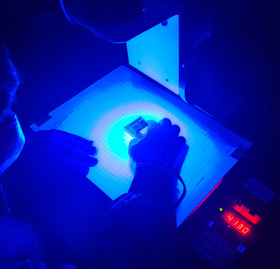

- Fluorescent penetration inspection may only be carried out by a certified inspector as per the NAS410.

- The fluorescent penetrant is capable of penetrating upto the very finely opened hole (crevice).

- The fluorescent penetrant contains fluorescent pigment which shines with yellowish green color when exposed to the ultraviolet rays.

- The fluorescent indicators detected under the ultraviolet rays shall be deciphered according to the passing criteria applicable to the product.

2) Products to Apply

- This inspection method is applicable to the nonporous metals and nonmetals.

3) Process Flow Chart

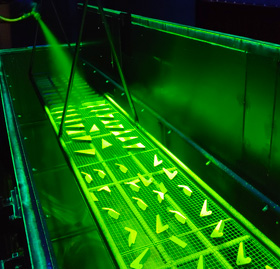

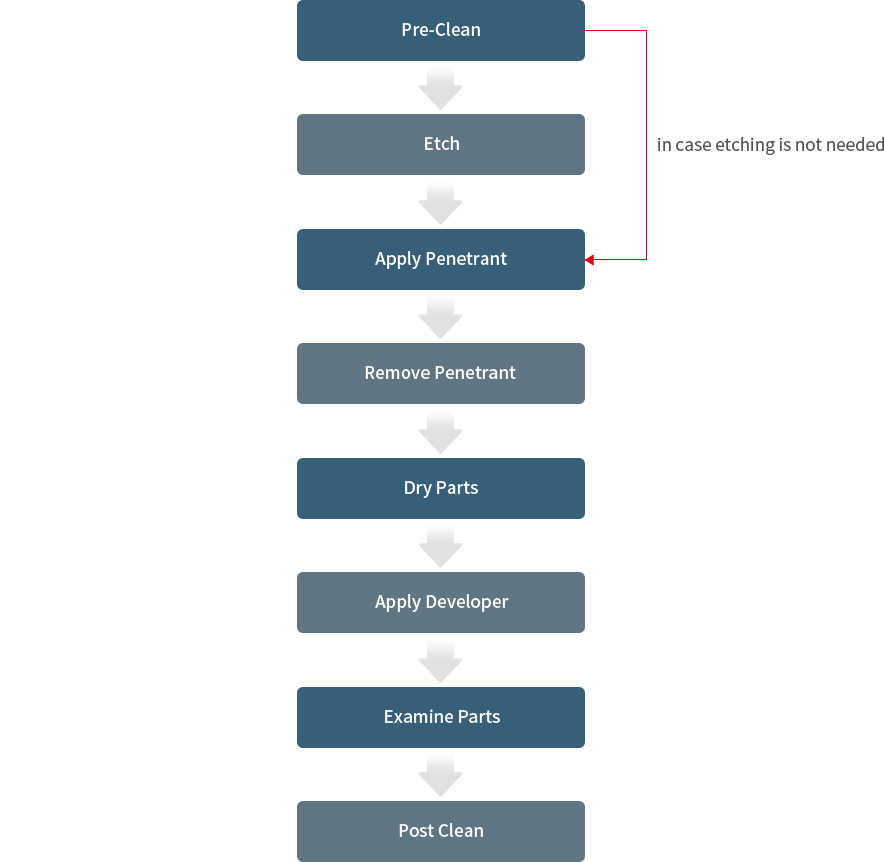

- [Pre Clean/Etch] → [Apply Penetrant] → [Remove Penetrant] → [Dry Parts] → [Apply Developer] → [Examine Parts] → [Post Clean]

Status of the Process Approval

- NADCAP

BSS7039, BAC5423 / HP6-13 / AITM6-1001 / NE07-001 / RRP58003 / P3TF2, P3TF47 / HGS1010, EMS52309, EMS92358 etc. - KSPC

ASTM E 417 / 81QD009 /A88MP0023 / FA84MP0411 etc.

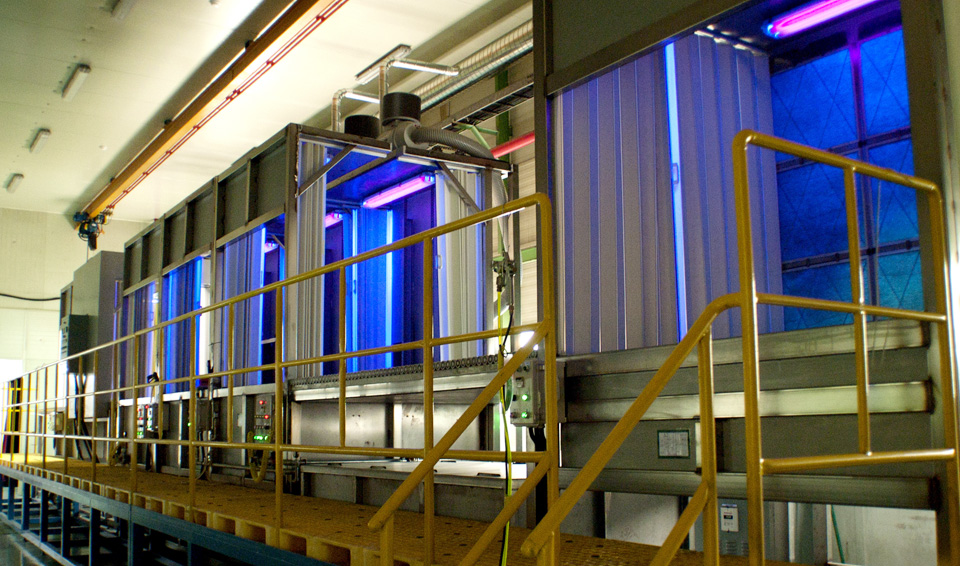

Status of Production Facilities

- FPI #1 (Type 1 Method A, Form a & d)

3400(L) x 1400(H) x 800 mm (W) - FPI #2 (Type 1 Method A, B(or D), Form a & d)

1700(L) x 1700(H) x 1600 mm (W)